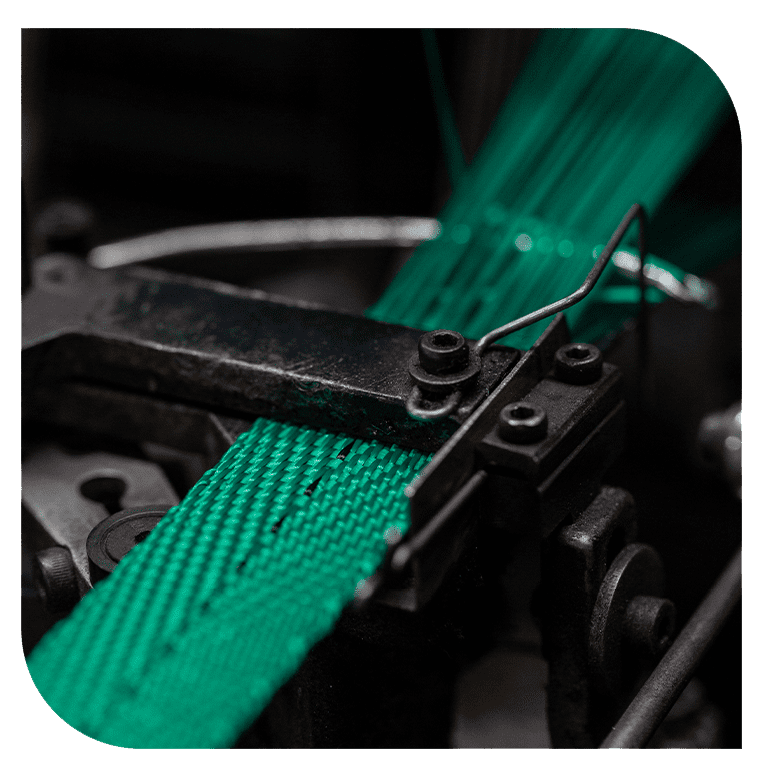

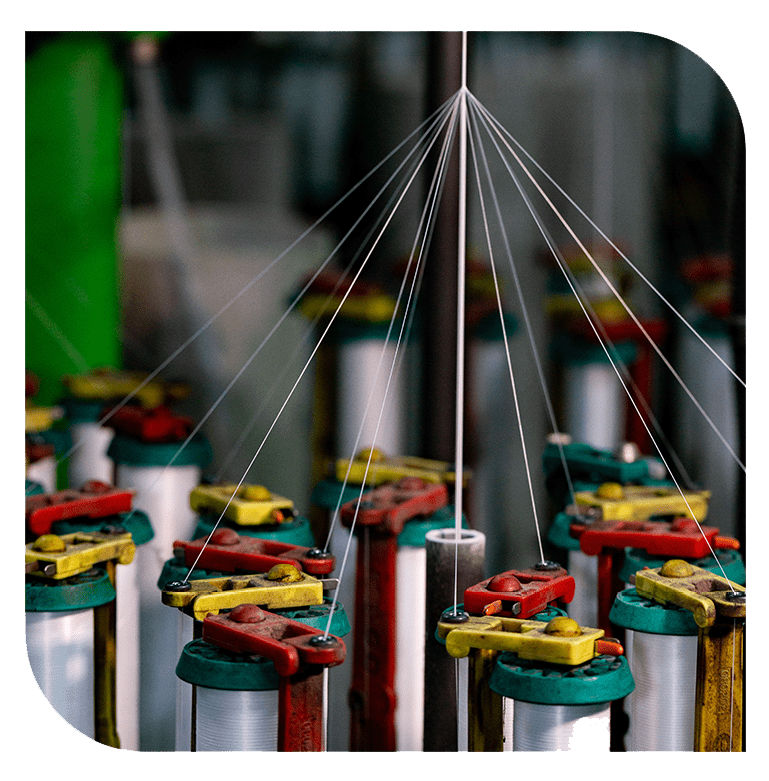

Behind every GRC product lies a narrative of dedicated refinement and innovative problem-solving spanning years. Envisioned with love, crafted with care, and delivered with unwavering devotion, our products seamlessly weave proven technology with years of experience, creating not just products but stories of passion embedded in every detail.

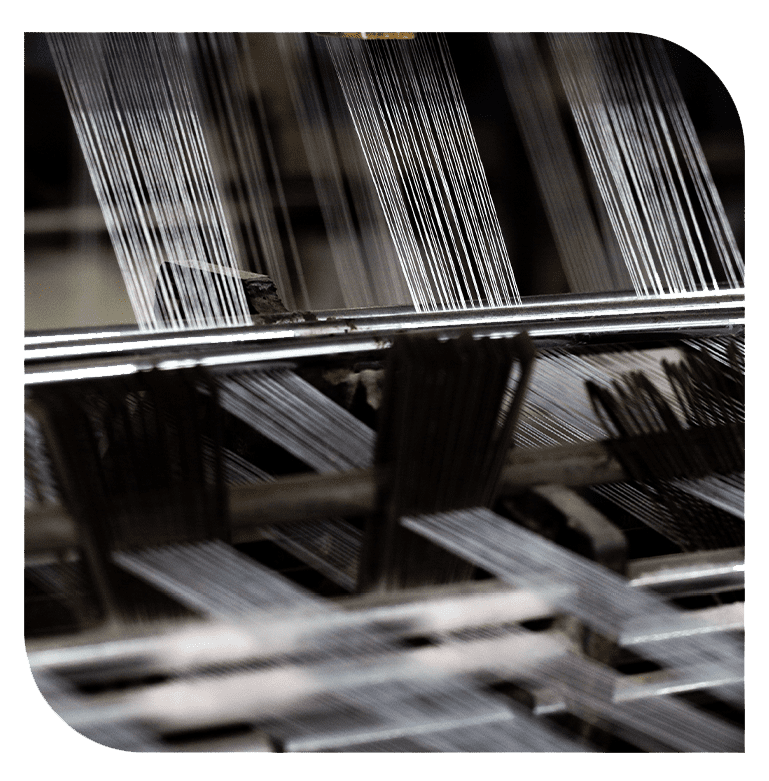

With decades of dedicated service, our team epitomizes unparalleled expertise, actively embracing technological advancements. Their commitment extends beyond tradition, integrating cutting-edge technology seamlessly. Seasoned professionals nurture knowledge sharing, playing a pivotal role in training, ensuring our team meets industry demands. This commitment to tradition and innovation is GRC's cornerstone, upholding high standards of craftsmanship and technological prowess.

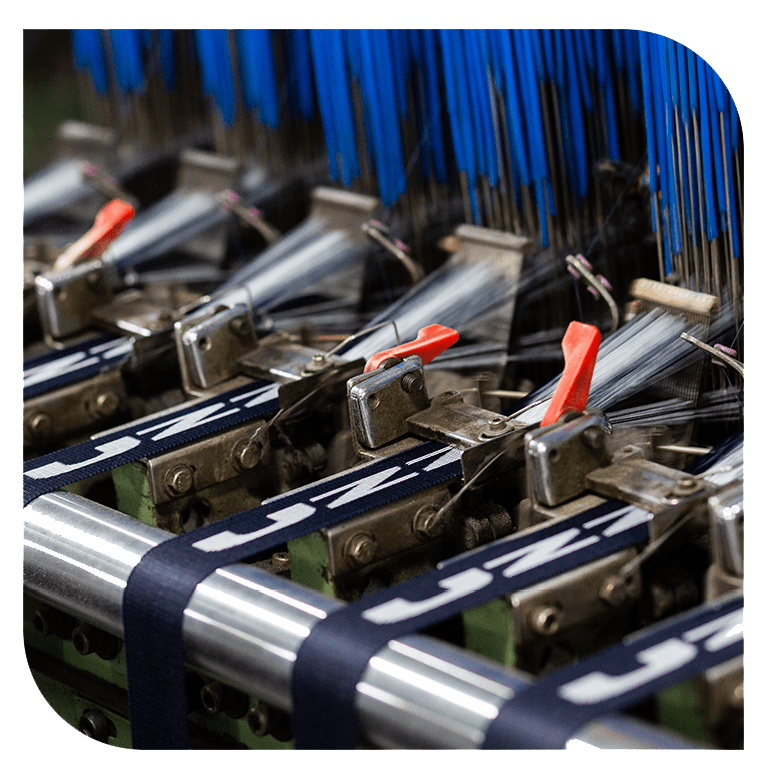

Every GRC product is envisioned with love, crafted with care, and delivered with devotion. Our products reflect our passion in every detail

With decades of service, our team embodies unparalleled expertise and embraces technological advancements. Their commitment to tradition and innovation ensures high standards of craftsmanship and technological prowess, supported by seasoned professionals who share their knowledge and train the next generation